USES AND CHARACTERISTICS

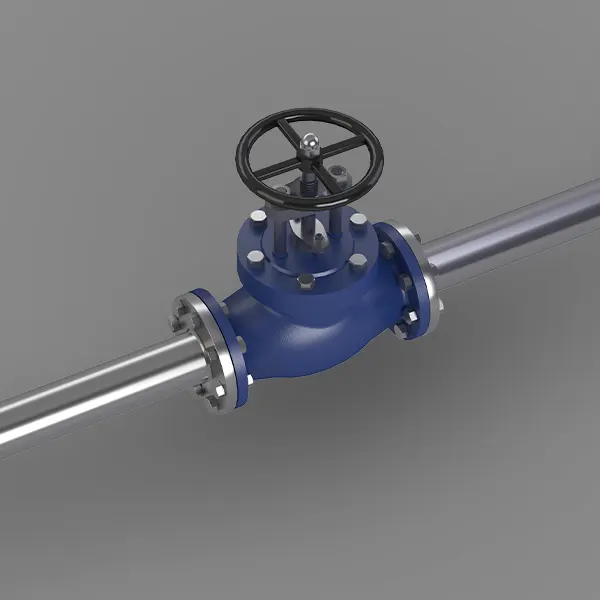

fittings without insulation

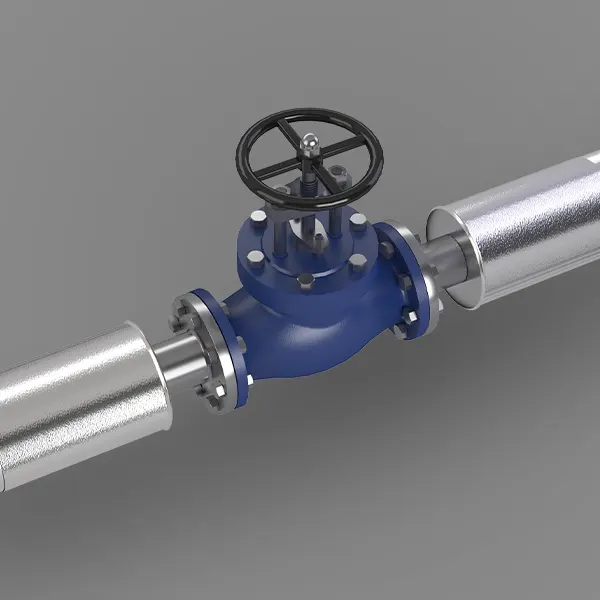

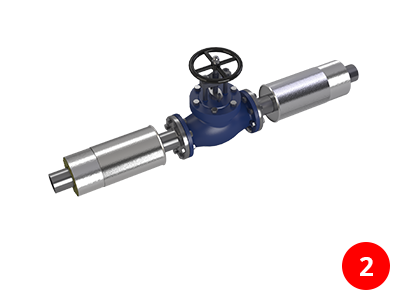

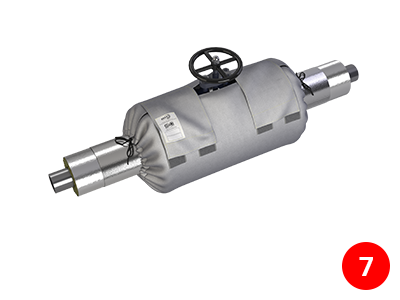

fittings with insulation

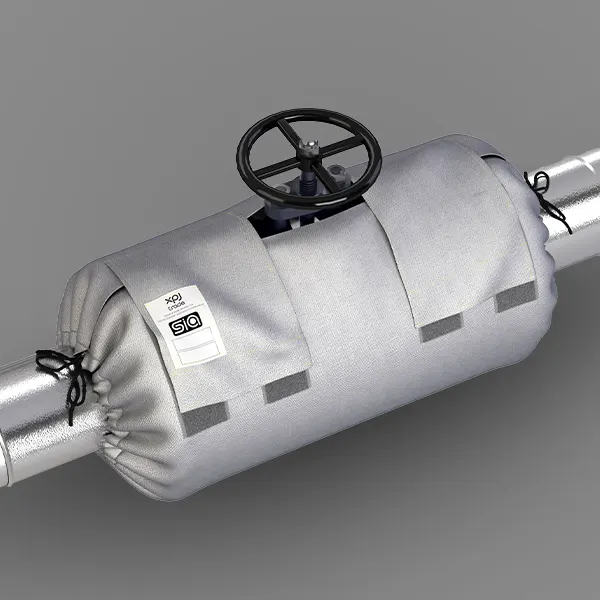

fittings with insulation and SIA installation

QUALITY INSULATION = ENERGY SAVINGS = REDUCTION IN CO2 = CARE FOR THE ENVIRONMENT

SIA products are used primarily for applications with health protection requirements for operators – against burns and to reduce thermal losses leading to a reduction in energy costs of individual devices, such as pipelines, fittings in boiler rooms and other kinds of equipment.

SIA removable insulation for fittings is supplied in two different types (SIA H and SIA P) from standard dimensions all the way to atypical dimensions produced to order.

-

-

- SIA H – for a maximum medium temperature of 150 °C – thickness of insulation 40 mm.

- SIA P – for a maximum medium temperature of 250 °C – thickness of insulation 60 mm.

-

The SIA standard product range is produced according to standardised named brightness levels for a rated pressure of PN16 in individual fittings. For non-standard types of fittings and devices a proposal is prepared according to the client’s design specifications or based on in-place measurements with subsequent price calculation. You can also fill in a non-binding inquiry asking for a price calculation.

SIA removable insulation is comprised of three functional layers:

- Heat resistant fabric on the internal surface, which is in contact with the insulated equipment.

- The insulation used is a mineral slat with aluminium foil in different thicknesses.

- Heat resistant external fabric finish.

ADVANTAGES OF SIA – REMOVABLE INSULATION

fast and simple

assembly and disassembly

easy

maintenance

washable

jacket

long

lifetime

health

and safety

energy

savings

rapid return

on investment

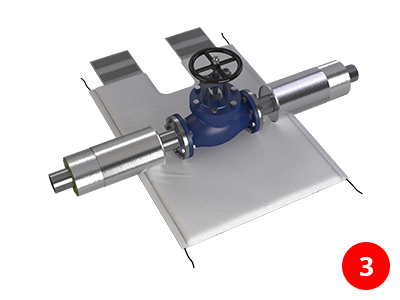

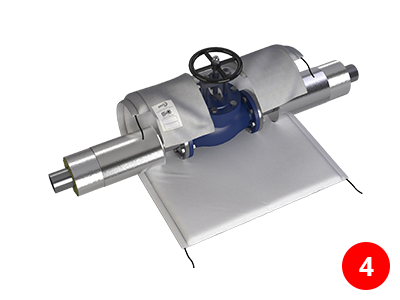

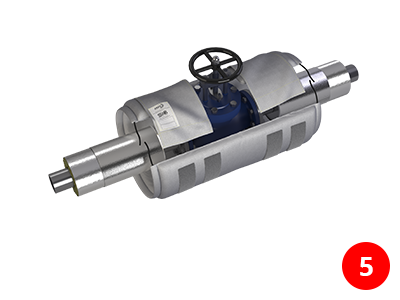

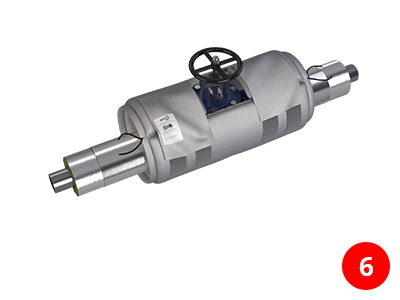

SIA Instalation Process

SIA installation must only be carried out on valves out of service to prevent burns

insulated section

mpleted pipe insulation before and after the valve, including surface treatment (e.g. cladding)

SIA insulation stretched under the fitting with white fabric to the insulated surface so that the fabrics are on the sides

pulling the back of the SIA towards you partial connection of the front section with Velcro fasteners to the rear section with flaps

partial connection of the front part with Velcro fasteners to the back part with flaps

pulling both ends of the SIA together and fixing the Velcro flaps

tightening and fastening the Velcro flaps and tying the laces